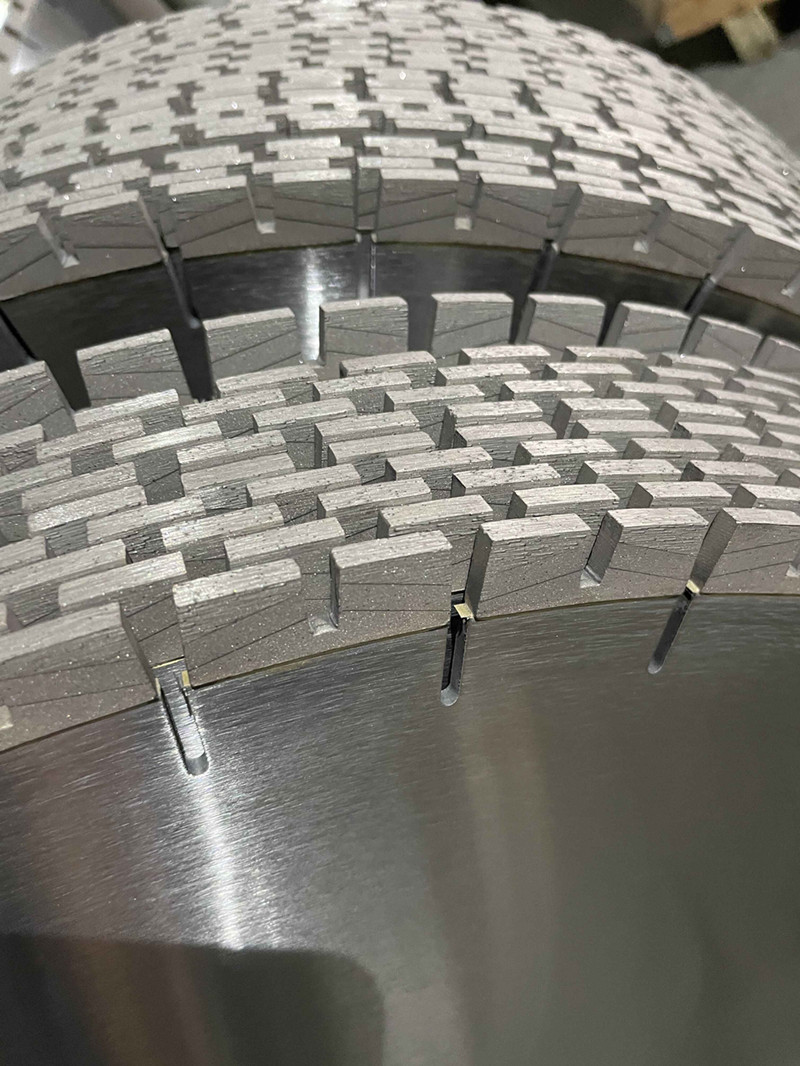

1.Duba diamita na ciki da waje na igiyoyin gani, kauri da adadin hakora na substrate bisa ga bukatun samarwa, kuma duba ƙayyadaddun, adadi da radian na ɓangaren lu'u-lu'u.Sa'an nan kuma niƙa da m chamfer na substrate a kan miya kayan aiki.Tsaftace saman walda na tushe da sashi tare da maɓallin C, sannan a yi amfani da wakili na siyarwa.

2.Zaɓi madaidaicin walƙiya mai dacewa bisa ga ƙayyadaddun ƙirar gani a cikin buƙatun gini.Nisa na ruwan walda gabaɗaya ya fi 0 girma fiye da kaurin tushe.A kauri daga waldi ruwa zai zama 0.25-0.30mm lokacin waldi da saw ruwa da diamita na 5-1 mm kuma fiye da 1500mm;Lokacin waldi da saw ruwa da diamita kasa da 1500mm, da kauri daga cikin waldi ruwa zai zama 0.15 ~ 0.25mm.

3.Install tushe, daidaita matsayi, ƙara ƙulla gyaran gyare-gyare, saka splint mai sanyaya, daidaita na'urar turawa da sashi, daidaita yanayin walda, adana zafi da lokacin sanyaya bisa ga buƙatun tsari, da aiwatar da aiwatarwa. waldi.

4.Lokacin walda da saw ruwa tare da high-mita kayan aiki, juya tushe 180 ° C ga kowane kashi welded, don haka kamar yadda weld symmetrically don kauce wa annealing ko gida nakasawa lalacewa ta hanyar overheating na tushe.

5.Lokacin walda gang saw ruwa, weld da kashi zuwa kayyade matsayi bisa ga hakora layout.

6. Bayan walda igiya, za a gudanar da binciken kai.

Lokacin aikawa: Maris-04-2023