1.Menene rawar kowane kashi a cikin lu'u-lu'u ya juya matrix nesta?

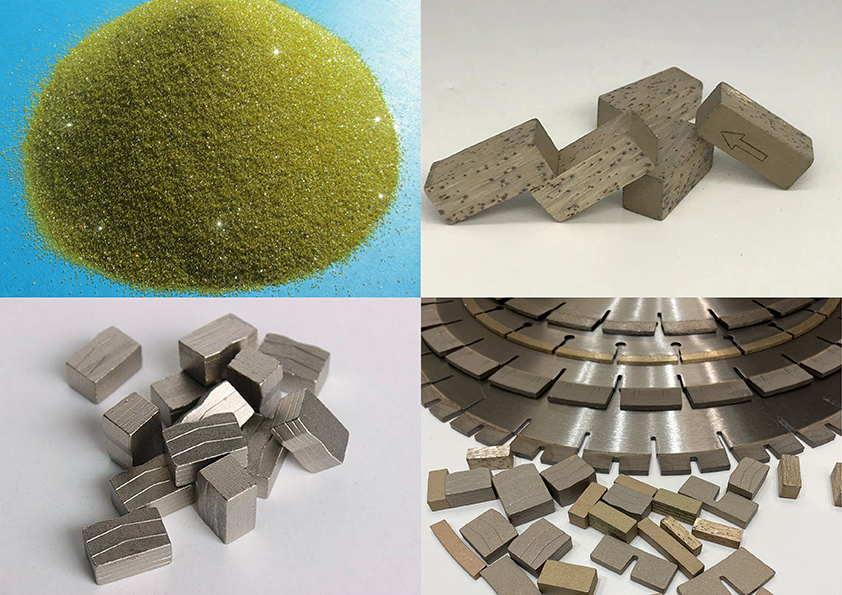

Matsayin tagulla: Garin jan ƙarfe da jan ƙarfe sune mafi yawan ƙarfe da ake amfani da su a cikin kayan aikin lu'u-lu'u na ƙarfe, tare da foda na jan ƙarfe na electrolytic shine mafi yawan amfani.Jan ƙarfe da jan ƙarfe a tushen Alloys ana amfani dashi sosai saboda jan ƙarfe mai gamsarwa suna da cikakkun kaddarorin: ƙananan zazzabi, da kuma rashin gaskiya tare da wasu abubuwan.Kodayake jan ƙarfe ba ta da lu'u-lu'u webonds, wasu abubuwan da kuma alloes na tagulla na iya inganta rayuwarsu da lu'ulu'u.Ofaya daga cikin abubuwan kamar su cr, ti, w, v, fe da za a iya amfani da jan ƙarfe da carboyes da yawa na rigar allos akan lu'u-lu'u.Kararwar jan ƙarfe a baƙin ƙarfe ba ta da girma.Idan akwai wuce kima mai wuce kima a cikin baƙin ƙarfe, yana da matuƙar rage aikin zafi kuma yana haifar da abubuwan fashewa.Uwararri na iya samar da ingantattun hanyoyin da aka fifita shi tare da nickel, cobalt, manganese, tin, da zinc, karfafa matrix karfe.

Aikin Tin: Tin shine kashi wanda yake rage yawan tashin hankali na alloyuna ruwa kuma yana da tasirin rage kusurwar da ke kan lu'u-lu'u.Abu ne wanda ke inganta wallenan wasan karafa a lu'u-lu'u a lu'u-lu'u, yana rage yanayin narkewar alloli, kuma yana inganta tsari na latsa.Don haka ana amfani da sl sosai a adhere, amma amfaninta yana iyakance saboda babban ƙarfinsa.

Matsayi na zinc: a cikin kayan aikin lu'u-lu'u, zn da sn da yawa iri-iri, kamar su m narkewa da m narke da kyau m, yayin da Zn ba ya da kyau a canyar da lu'u-lu'u kamar sn.A matsa lamba na karfe na zn yana da girma sosai kuma yana da sauƙin kare, don haka yana da mahimmanci a kula da adadin ZN da aka yi amfani da shi a cikin kayan aikin lu'u-lu'u.

Matsayin aluminum: aluminum na ƙarfe shine m haske da karfe mai kyau Deoxizer.A 800 ℃, kusurwar mayafi na Al akan lu'u-lu'u shine 75 °, kuma a 1000 ℃, kusurwar mayafi shine 10 °.Dingara kayan foda a cikin bidinum na kayan aikin lu'u-lu'u na iya samar da cututtukan lokaci na Carbide Ti å alC da intanet a cikin Matrix Alloy.

Aikin baƙin ƙarfe: baƙin ƙarfe yana da rawar jiki a cikin sanyaye, ɗaya shine don samar da carburitized carding tare da lu'u-lu'u tare da wasu abubuwan don ƙarfafa matrix.Wethearfin baƙin ƙarfe da lu'u-lu'u ya fi na tagulla da tagulla, da kuma miyagun aiki tsakanin baƙin ƙarfe da lu'u-lu'u ya fi na Combalt.Lokacin da adadin da ya dace na carbon ya narke a cikin Fit tushen Alloys, zai zama da amfani ga ɗaurin su tare da lu'u-lu'u.Matsakaici na matsakaici na Diamonds by Fit tushen alloys na iya ƙara yawan haɗin tsakanin faifai da lu'u-lu'u.Facturin cikewa ba shi da laushi kuma ba shi da kyau, amma an rufe shi da wani Layer na POYY, wanda alama ce ta haɓaka ƙarfin haɗin gwiwa.

Matsayin Cobalt: CO da fe da feta na hanyoyin canzawa, da kuma halaye da yawa iri daya ne.C na iya samar da Carbide CO ₂ c tare da lu'u-lu'u a karkashin takamaiman yanayi, yayin da kuma yada wani fim mai ban mamaki comball a farfajiya na lu'u-lu'u.Ta wannan hanyar, CO CO na iya rage tashin hankali na ciki tsakanin CO da Diamond, kuma yana da babban aiki mai mahimmanci zuwa lu'u-lu'u a cikin lokacin ruwa, yin kyakkyawan kayan haɗin kai.

Matsayin Nickel: A cikin bidin kayan aikin lu'u-lu'u, ni shine tushen da ba makawa.A cikin Allos na Cuits, ƙari na Ni, ƙarfafa narkar da Cu, da kuma ƙara ƙarancin narkewar m ƙarfe, da kuma sanya resistance.Dingara ni da cu zuwa fela alloyes na iya rage zafin jiki na kiwo kuma suna rage lalata ƙwayar thermos na boned karafa a kan lu'u-lu'u.Zabi hade da haɗin da ya dace da f da Ni na iya inganta ikon ɗaukar nauyin fina-hadar gwiwa a kan lu'u-lu'u.

Matsayin Manganese: A cikin ƙarfe da ke ɗaure da ƙarfe, manganese yana da irin wannan sakamako ga baƙin ciki, amma yana da ƙarfin ikon da deoxygenation.Additionarin adadin MN gabaɗaya ba shi da yawa, kuma babban abin lura shine don amfani da Mn don lalacewa yayin bikin.Sauran mn na iya shiga cikin kulawa da karfafa matrix.

Matsayin Chromium: Chromumy cromium ne mai ƙarfi carbide-kirkirar kashi kuma wani abu da aka yi amfani da shi.A cikin Groove Groove sayan matrix, akwai isasshen Chromium don samun sakamako mai kyau, wanda ke da alaƙa da makamashi makamashi na cr.Dingara wani karamin adadin cr ga matrix na cuitx na iya rage rigar kwana na tagulla a tushen lu'u-lu'u a lu'u-lu'u a lu'u-lu'u.

Matsar da titanium: titanium ƙaƙƙarfan carbide ne form mai sauƙi wanda yake da sauƙi ga oxidize da wuya a rage.A gaban oxygen, ti yadda aka ƙaddara yana haifar da TiO2 maimakon tic.Titanium karfe abu ne mai kyau na tsari mai ƙarfi, ƙarancin ƙarfi a yanayin zafi, juriya da zafi, lalata m jingina, da kuma melroven hali.Bincike ya nuna cewa ƙara adadin titanium ga lu'u-lu'u ga lu'u-lu'u ya juya don inganta rayuwar sabis na sagin.

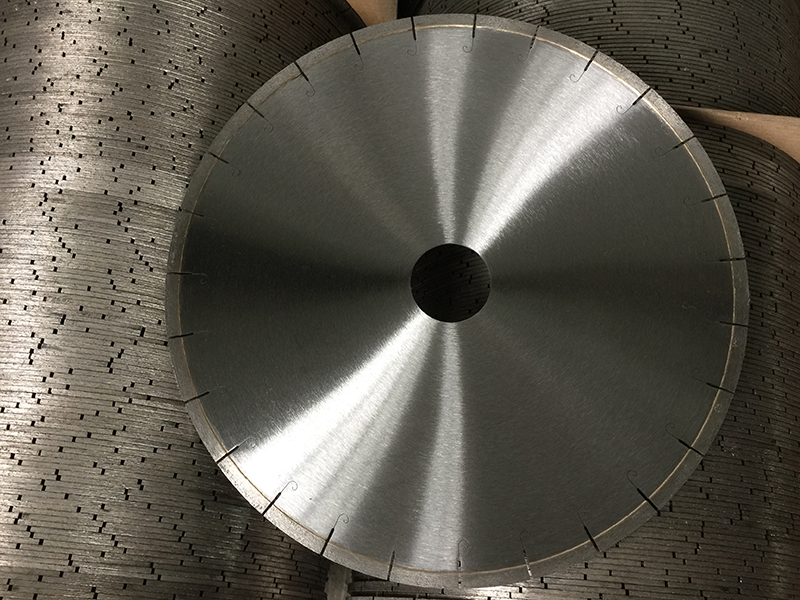

2.Me yasa jikin ganga zai dace da dutsen yanke?

Babban hanyoyin tsirar dutsen a lokacin da aka gaji tsarin yanke tsari da murkushe, har ma da babban ƙarfafawa, an gyara shi ta hanyar nika.Lu'u-lu'u tare da m aiki wurin da ke aiki a matsayin kayan aikin yankan.Edge na yankan shine yanki mai lalacewa, yankin yankan yana gaban gefen gefen, kuma yanki mai nika yana kan gefen baya.A karkashin yanke-gudun-high-Speed, barbashi lu'u-lu'u aiki akan goyon bayan matrix.A lokacin aiwatar da yankan dutse, a gefe guda, lu'u-lu'u ya shaƙe zane-zane, rarrabuwa, da defachent saboda matsanancin zafin jiki ya haifar da tashin hankali;A gefe guda, an sanya matrix ta hanyar tashin hankali da lalacewa na dutse da kuma foda na dutsen.Sabili da haka, batun daidaitawa tsakanin ruwan wukake da dutse shine ainihin batun sanya kuɗi tsakanin lu'u-lu'u da matrix.Halin kayan aiki wanda ke aiki a al'ada shine rashin daidaitaccen ya dace da matrix, ba mai santsi da sikelin lu'u-lu'u da ke amfani da shi A yayin aiki, sakamakon shi da lu'ulu'u da yake kasancewa a cikin ɗan ƙaramin rauni da kuma rashin sani.Idan ƙarfi da kuma juriya tasirin lu'u-lu'u da aka zaɓa sun yi ƙasa, zai haifar da al'aurawar "kufai", da kuma sawling ba zai motsa ba;Idan wuce gona da iri masu yawa barbashi barbashi an zaɓi, gefen yankan barbashi zai bayyana a cikin ƙasa mai lalacewa, wanda ya haifar da karuwa cikin yankan ƙarfi da raguwa a cikin sarrafawa.

(1) Idan saurin saurin matrix ya fi na lu'u-lu'u, yana haifar da cirewar lu'u-lu'u da yawa.The sa juriya na sawwa ya yi kasa da kasa, kuma da rayuwarsa ta santsi ce takaice.

(2) Lokacin da aka sanya saurin matrix bai wuce na lu'u-lu'u ba, ana iya samun sabon lu'u-lu'u bayan gefen yankan lu'u-lu'u yana da rauni sosai, farfajiya na Serress ana iya wucewa, saurin yankewa yana da jinkirin, kuma yana da sauƙin haifar da yanke allon ya faɗi, yana shafar ingancin aiki.

(3) A lokacin da saurin saurin matrix yayi daidai da saurin saurin yanayin lu'u-lu'u, yana nuna daidaituwar matrix tare da lalacewar dutse.

Lokacin Post: Aug-11-2023